Recirculating Sand Filters (RSFs) Guide

RSFs, or recirculating sand filter systems are a modernized version of the classic open sand filter design. This adaptation removed the odor problems associated with traditional sand filters due to its recirculation capability, which injects oxygen into effluent that distributes across the filter bed.

RSFs are ideal for sites with shallow soil cover, low permeability, high groundwater levels and limited land area. They work via physical and chemical processes to remove contaminants in wastewater but are most effective due to their capacity for biological processes.

Recirculating Sand Filters (RSFs) Uses

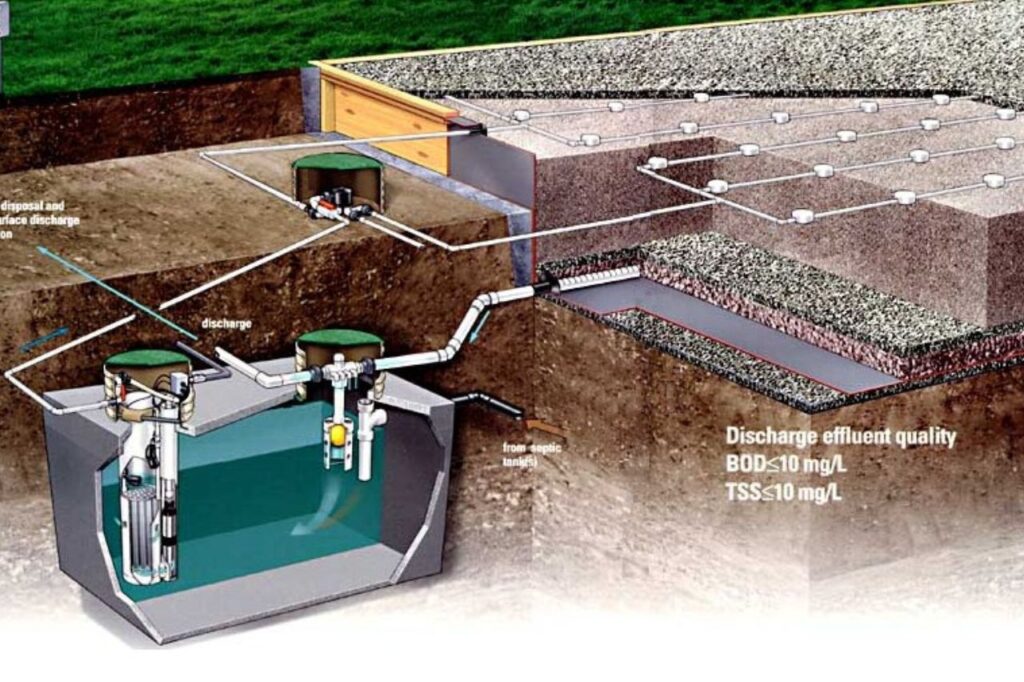

Recirculating sand filters (RSFs) are typically used for homes or other small-scale operations. The process begins with the wastewater being channeled into a septic tank where primary treatment occurs.

The partially treated water is then sent to a recirculation tank, where it mixes with sand filter filtrate before being pumped back to the sand filter bed for further filtering. The size of the recirculation tank should be equivalent to at least one day’s raw sewage volume or follow local guidelines.

Advantages and Disadvantages of Recirculating Sand Filters (RSFs)

Advantages: No need for chemicals; excellent effluent quality with over 95% BOD and TSS removal; expandable through modular design; effective in high-level BOD applications; easily monitored and maintained without special skill; significant Nitrogen reduction achievable; substitute medium may be found if sand is not possible locally, using less land area than a single-pass sand filter.

Disadvantages: Higher costs if appropriate local media not available; weekly maintenance required for media, pumps and controls; design must factor in cold temperatures.

Recirculating Sand Filters (RSFs) Design

Design elements of the RSF system must consider the sand media depth, graded gravel base, recirculation tank, dosing rate and timing, underdrains, discharge line, freezing prevention in colder climates and insulation. The 2-foot-deep sand filter has a layer of gravel beneath it for support and surrounding the underdrain system.

The mixture of septic tank effluent and sand filtrate is dosed by a submersible pump controlled by a programmable timer in the control panels. Filtration occurs as the filter effluent enters the bottom underdrains before collecting in the recirculation tank.

Before leaving the tank, a rubber ball helps to ensure proper outlet flow from higher elevations within the tank. To prevent freezing in very cold climates, distribution lines must be able to drain between doses and tanks while adding insulation to both filter and tank components.

Recirculating Sand Filters (RSFs) Performance

Performance of a recirculating sand filter (RSF) system is determined by several factors, including the type and biodegradability of the wastewater, environmental conditions within the filter, pretreatment degree, size and uniformity of the granular material used as media, hydraulic loading rate, organic loading rate, and dosing techniques.

The coveted high-quality effluent has been shown to attain 85-95% BOD and TSS removal rates with almost complete nitrification and even denitrification potential; however, this highly depends on modifications in design and operation for given conditions. Temperature in particular has an effect on rate of microbial growth and chemical reactions that stabilize wastewater.

The finer the grain size, the slower the filtration rate but with higher quality effluent. Additionally, increasing hydraulic loading or organic loading can result in shorter filter life or even decreased performance.

Operation and Maintenance of Recirculating Sand Filters

O&M is relatively easy and does not require extensive maintenance. Tasks include inspecting the dosing equipment, monitoring influent and effluent levels, maintaining the filter surface, checking heads on orifices, flushing the manifold annually, and keeping the sand bed free from weeds.

Septic tanks in particular need to be checked often for sludge and scum buildup, as well as being pumped when necessary. To reduce costs, local materials should be used for the media in the filter system. Additionally, one hour of inspection should be carried out monthly on all components of the RSF system for optimal performance.