Are you curious about the inner workings of a vacuum drainage system? Look no further, as we dive into the secrets behind this innovative technology. Vacuum drainage systems offer a revolutionary solution for efficiently and effectively removing wastewater from buildings. Unlike traditional gravity-based systems, vacuum drainage systems operate under negative pressure, allowing for greater flexibility in installation and maintenance. Whether you are an engineer, a building owner, or simply someone intrigued by the marvels of modern plumbing, join us on this journey as we unravel the secrets of how a vacuum drainage system works.

Key Takeaways:

- Vacuum drainage systems operate under negative pressure, offering greater flexibility in installation and maintenance compared to traditional gravity-based systems.

- The key components of a vacuum drainage system include the vacuum station, piping network, and collection points with specially designed traps.

- The system works based on the principle of differential pressure, where the vacuum pump generates negative pressure to rapidly transport wastewater through the pipes.

- Vacuum drainage systems provide advantages such as increased design flexibility, reduced installation and maintenance costs, water savings, and improved environmental friendliness.

- These systems find applications in various settings, including high-rise buildings, underground structures, ships, and remote areas with limited access to sewage infrastructure.

The Components of a Vacuum Drainage System

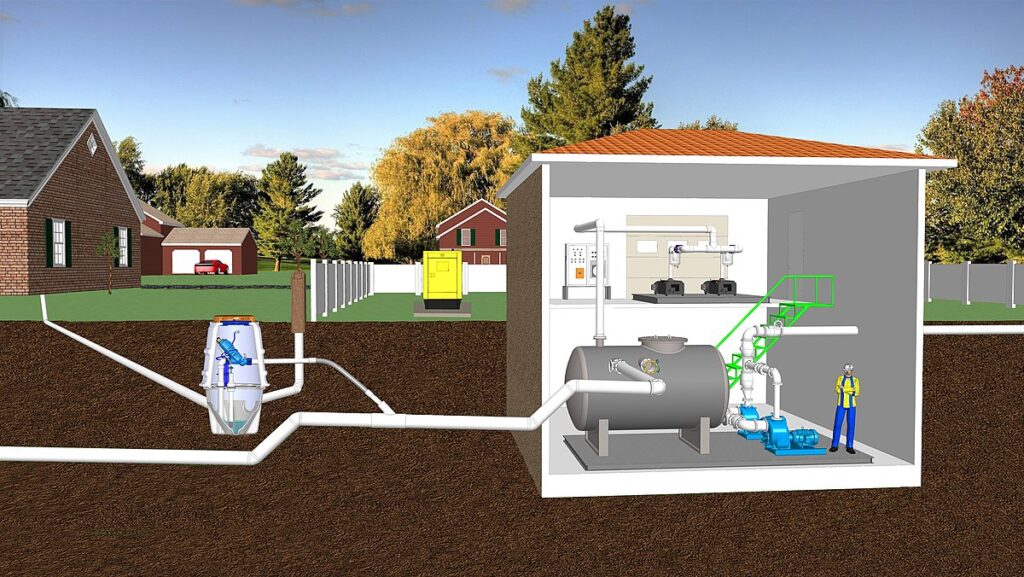

A vacuum drainage system consists of several key components that work together to ensure the smooth and efficient removal of wastewater. At its core, the system comprises three main parts: the vacuum station, the piping network, and the collection points.

The vacuum station is the heart of the system. It houses the vacuum pump, which generates the negative pressure required to transport the wastewater. The pump creates a vacuum in the system, causing the wastewater to be sucked out of the building and into the collection tank. Additionally, the vacuum station contains various valves and sensors that control the flow of wastewater and monitor the system’s performance.

The piping network is responsible for transporting the wastewater from the collection points to the vacuum station. Made from durable materials such as PVC or stainless steel, the pipes are designed to withstand the negative pressure and ensure leak-free operation. The network is also equipped with air admittance valves, which allow air to enter the system to prevent the formation of a full vacuum.

Collection points are strategically placed throughout the building to capture wastewater from various sources, such as toilets, sinks, and showers. These collection points are connected to the piping network and feature specially designed traps that prevent foul odors and gases from escaping back into the building.

How Does a Vacuum Drainage System Work?

Now that we have a basic understanding of the components, let’s delve into the fascinating science behind the operation of a vacuum drainage system. The system relies on the principle of differential pressure to transport wastewater.

When a toilet is flushed or a sink is drained, the wastewater flows into the collection point. As the wastewater enters the collection point, the air inside is displaced, creating a pressure difference. This pressure difference triggers the opening of the air admittance valve, allowing air to enter the system and equalize the pressure.

Once the pressure is equalized, the vacuum pump at the vacuum station activates, creating a negative pressure within the system. This negative pressure causes the wastewater to be rapidly sucked out of the collection point and into the piping network. The vacuum pump continues to operate until all the wastewater has been transported to the collection tank.

To ensure the system operates smoothly, each collection point is equipped with a one-way valve that prevents wastewater from flowing back into the building. This valve ensures that the negative pressure remains constant, allowing for the continuous removal of wastewater.

Advantages of Using a Vacuum Drainage System

The use of a vacuum drainage system offers several advantages over traditional gravity-based systems. One of the main advantages is the flexibility it provides in building design and layout. Unlike gravity systems, which require a certain degree of slope for wastewater to flow, vacuum systems can be installed in buildings located in low-lying areas or those lacking sufficient slope.

Another advantage is the reduced installation and maintenance costs. Vacuum systems require smaller diameter pipes, which are easier and cheaper to install compared to the larger pipes required in gravity systems. Additionally, the negative pressure in vacuum systems helps prevent the buildup of solid waste and debris in the pipes, reducing the need for frequent maintenance and cleaning.

Furthermore, vacuum drainage systems are more environmentally friendly. The use of negative pressure reduces the amount of water required to flush toilets, resulting in significant water savings. Additionally, the air admittance valves prevent the escape of foul odors and gases, creating a more pleasant and hygienic environment.

Applications of Vacuum Drainage Systems

Vacuum drainage systems have a wide range of applications and can be used in various settings. They are particularly suitable for buildings where gravity drainage systems are not feasible or practical. Some common applications include high-rise buildings, underground structures, ships, and remote areas with limited access to sewage infrastructure.

In high-rise buildings, vacuum systems enable efficient wastewater removal without the need for extensive and costly pipe installations. The negative pressure allows for vertical transportation of wastewater, eliminating the need for multiple sewage pumps typically required in gravity systems.

In underground structures, such as basements and parking garages, vacuum drainage systems provide an effective solution for removing wastewater without the need to rely on gravity. The compact design of the system makes it ideal for limited spaces.

On ships, vacuum drainage systems are essential for managing wastewater in a confined environment. The negative pressure allows for efficient removal of wastewater, ensuring the ship remains clean and hygienic.

In remote areas with limited access to sewage infrastructure, vacuum drainage systems offer a cost-effective and efficient solution. The flexibility of installation and the ability to transport wastewater over long distances make vacuum systems a viable option for these locations.

Common Misconceptions about Vacuum Drainage Systems

Despite the numerous advantages, there are still some misconceptions surrounding vacuum drainage systems. One common misconception is that the negative pressure in the system poses a risk of wastewater backup. However, this is not the case. The one-way valves installed at each collection point prevent the backflow of wastewater, ensuring the system operates smoothly and efficiently.

Another misconception is that vacuum systems are noisy. While it is true that the vacuum pump generates some noise during operation, modern vacuum systems are designed with noise reduction in mind. The noise levels are carefully controlled to ensure minimal disruption to building occupants.

Maintenance and Troubleshooting of Vacuum Drainage Systems

Like any other system, vacuum drainage systems require regular maintenance to ensure optimal performance. Routine inspections and cleaning of collection points, pipes, and valves are necessary to prevent blockages and maintain the system’s efficiency.

In the event of a system malfunction, troubleshooting is essential to identify and rectify the issue promptly. Common problems include leaks, blockages, and valve failures. Engaging the services of trained professionals who specialize in vacuum drainage systems is crucial for efficient troubleshooting and repair.

Comparing Vacuum Drainage Systems with Traditional Gravity Drainage Systems

While both vacuum drainage systems and traditional gravity drainage systems serve the same purpose of removing wastewater, there are significant differences between the two.

Gravity drainage systems rely on the force of gravity to transport wastewater. The pipes in these systems must be installed at a slope to ensure proper flow. This requirement can limit the design and layout of buildings, especially in areas with low elevation or limited space.

On the other hand, vacuum drainage systems operate under negative pressure, allowing for greater flexibility in building design and layout. The smaller diameter pipes used in vacuum systems are easier and cheaper to install compared to the larger pipes needed in gravity systems.

Vacuum systems also offer enhanced environmental benefits. The negative pressure reduces water consumption, resulting in water savings. Additionally, the prevention of foul odors and gases contributes to a healthier and more pleasant environment.

Case Studies of Successful Vacuum Drainage System Implementations

Numerous successful implementations of vacuum drainage systems can be found worldwide. One such case study is the Oslo Opera House in Norway. The opera house, situated on the waterfront, required an efficient wastewater management solution. The use of a vacuum drainage system allowed for the removal of wastewater without the need for extensive pipe installations or reliance on gravity.

Another example is the Marina Bay Sands integrated resort in Singapore. The resort’s iconic design presented challenges in wastewater removal due to its unique architecture. Vacuum drainage systems were chosen to overcome these challenges, ensuring efficient and reliable wastewater management.

Conclusion: The Future of Vacuum Drainage Systems

As technology continues to advance, vacuum drainage systems are poised to play an increasingly important role in modern plumbing. Their flexibility, efficiency, and environmental benefits make them an attractive choice for a wide range of applications. Whether it’s in high-rise buildings, underground structures, or remote areas, vacuum drainage systems offer a reliable and sustainable solution for wastewater management. With ongoing research and development, we can expect further improvements and innovations in vacuum drainage systems, revolutionizing the way we manage wastewater in the future.

In conclusion, the inner workings of a vacuum drainage system may seem complex at first, but understanding its key components and the science behind its operation reveals the genius behind this innovative technology. So, the next time you flush a toilet or wash your hands in a building equipped with a vacuum drainage system, you can appreciate the hidden marvels that make it all possible.

References:

https://www.airvac.com/en/case-studies/eco-services-baton-rouge-la